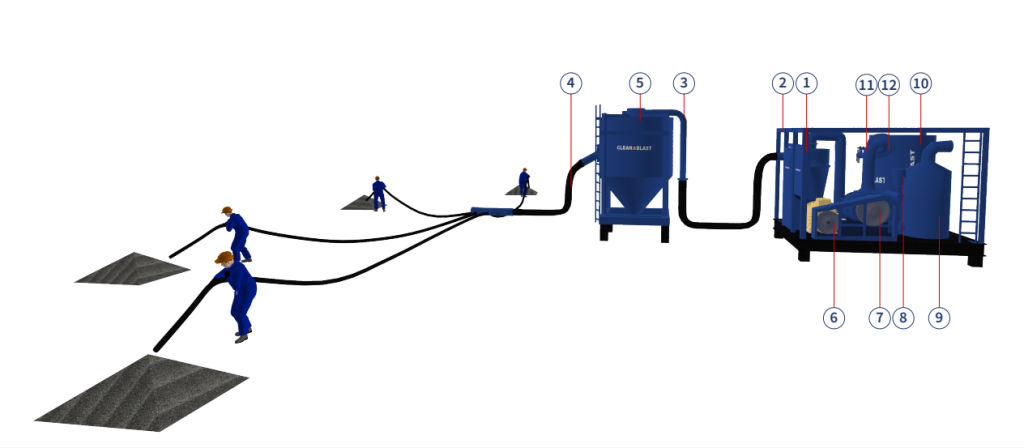

CBVR

- On-board Cyclonic Separator

- Site Crane Lifting Points

- Interconnecting Vacuum Recovery Hose

- Vacuum Recovery Hoses: Available from 20 m (66 ft) to 100 m (330 ft)

- Abrasive Recovery Silo Sizes

- Main Electric Drive Motor

- Vacuum Producing Blower Assembly

- Over Vacuum Safety Relief Valve

- Clean Air Discharge Silencer

- Polyester Cartridge Dust Collector System

- Reverse Pulse Jet Cartridge Cleaning System

- Vacuum Module Sizes

Main technical parameters

| Electrical Motor | 90kw, IP55, Class F | ||||

| Motor Rotation Speed | 1480rpm | ||||

| Motor Start | Delta | ||||

| Air Volume | 60m3/min | ||||

Shots/grits suction capacity | 3~10 tons/hVertical Suction 20m to 30m Horizontal machine to Silo 15m | ||||

| Max vacuum pressure | -0.0667Mpa/-450mmHg, vacuum relief valve | Over | Vacuum | Protection | by |

Dust removing system | Cyclone Dust Collector | 1set | |||

| Filtering Area | material: 64m2 | ||||

| Filter Material | High efficiency polyester fiber | ||||

| Filter Size | Ф325×1000mm ×4 pcs, 16m2/pc | ||||

| Dust emission density | ≤15mg/m3 | ||||

| Pulse Jet Control | It is controlled by PLC and do pulse jet by manual – auto pulse jet cleaning, Periodical pulse jet cleaning | ||||

| Noise | ≤85dB(A) @ 5m radius scale | ||||

| Compressed Air Required | it adopts outer compressed air and do pulse jet cleaning. The compressed air 0.6~0.8Mpa, 1.0m3/min | ||||

| Vacuum hose Size | Ф125mm / 5”× 20m, 1 pc | ||||

| Grit Hose Size | Ф4” × 30m, 1 pcФ2” × 20m, 2 pcs | ||||

| Size of Abrasive Storage Silo | About Φ1700×3250mm, Approx.8tons loading | ||||

| Outsize of equipment (L×W×H) | ≤2900×2200×2450mm | ||||

Electrical Control System , IP54 | 380V/50Hz/3PhKey parts from Schneider & CHINT/Delixi PLC by Siemens / MitsubishiLevel Indicator to inspect the dust level in cyclone dustremover | ||||

Accessories list of CBVR CH90 Abrasive vacuum Recovery System | 90kw Vacuum Recovery Machine, 1 unit | ||||

| Φ1700mm/8ton Abrasive Storage Tank, 1 unit | |||||

| Vacuum hose Φ5”×20m, 1pc | |||||

| Grit hose Φ4ʺ×30m, 1pc | |||||

| Grit hose for dust Φ2ʺ×20m, 2 pcs | |||||

| Connected and converted joint, 1 pc | |||||

| Certificate of Quality: 1 pc | |||||

| Manual Instruction Book: 1 pc | |||||

Features

CLEANBLAST vacuum recovery system provides 24-hours operation to recovering and conveying of blast medias, powders, plastic pellets, grains, sands, aggregates and other bulk materials in both clean-up and material transfer functions. Especially in inaccessible or enclosed areas such as storage tanks, box girder constructions, tank internals at shipyards etc, the equipment offers great savings in time and manpower. A CLEAN BLAST Vacuum system cut costs by reducing cleanup time and reclaiming valuable materials. These versatile vaccum systems can be used to pick up any materials that will flow through a hose with its long reach and powerful suction.

It allows silo to be emptied within a few minutes either manually or automatically. The silo can be fitted with a rotary-valve (optional) for continuous dumping operation.

Industrial Applications in

Shipyards

Fabrication companies

Tank cleaning companies

Metallurgical plants

Steel mills

Foundries

Power plants

Cement & chemical industries

Standard Safety Features

- System automatically shut-off to prevent damage to vacuum producer when suction hose is choked-up with abrasive and electric motor’s current rises above a certain predetermined value.

- Silo and cyclone are equipped with full-tank sensor to shut-off the vacuum machine when it is full and prevent overloading of abrasive to dust-collector. At the same time, it can also be engineered to activate the warning light and alarm (optional).

- An emergency ‘STOP’ button, when depressed, will automatically cut-off all electrical supply.

- pecification

Heavy Duty Range Specification

| Model No: | CBVR-E8-90 | CBVR-E10-110/132 |

| Recovery Rate | 3.5 to 8.0 Ton/Hr | 5.0 to 12 Ton/Hr |

| Max. Conveying Distance | 20m in Vertical ; 10m in Horizontal | 30m in Vertical ; 20m in Horizontal |

| Supply / Power / Class | 415V 3phase 50Hz/ 90KW Class F insulation & IP54 Protection | 415V 3phase 50Hz/110 KW or 132KW Class F insulation & IP54 Protection |

| Air Flow | 1470 cfm@ -450mm Hg | 2400 cfm@ -450mm Hg |

| Filter Cleaning | Periodic Reverse Jet Air Pulsing c/w Timer Card | Periodic Reverse Jet Air Pulsing c/w Timer Card |

| Dust Collector Filter | High Efficiency Filter Cartridge | High Efficiency Filter Cartridge |

| Dimension (LxWxH) | 2800 x 2800 x 2250mm | 3000 x 2300 x 2560mm |

| Silo Tank/Gross Weight (included) | 8 Ton Silo Tank / 3.5 Ton | 8 Ton Silo Tank / 4.5 Ton |

| Standard Accessories | 5ʺ x 10m Vacuum Hose, 5ʺ x 10m, 4ʺ x 20m Suction Hose, 2ʺ x 20m Hose | 6ʺ x 10m Vacuum Hose, 6ʺ x 10m, 5ʺ x 20m 4ʺ x 20m Suction Hose, 2ʺ x 20m Hose |

Medium Duty Range Specification

| CBVR 30 | CBVR 37 | CBVR 45 | CBVR 55 | CBVR 75 | |

| Recovery Rate (Ton/Hour) | 2.4 | 3 | 4.5 | 6 | 8 |

| Electric Motor | 30 KW | 37 KW | 45 KW | 55 KW | 90 KW |

| NG (rpm) | 3680 | 3680 | 3300 | 2965 | 3710 |

| NM (rpm) | 2945 | 2945 | 2955 | 2965 | 2970 |

| Q1 (m³/min) | 18.2 | 25.7 | 33.8 | 42.7 | 54.6 |

| t² (°C) | 67 | 67 | 66 | 66 | 65 |

| Max Noise Level | 80 | 85 | 85 | 85 | 90 |

| Electrical Supply | 380 Volt – 50 / 60 Hz | ||||

| Start Stop | With Star – Delta | ||||